Industrial machinery and manufacturing systems rely heavily on gears to transmit power efficiently, accurately, and reliably. Choosing the correct gear type can affect performance, efficiency, noise, and maintenance requirements. As a trusted gear manufacturer in India, Shreeji Gears has decades of experience designing and producing high-quality spur and helical gears for diverse industrial applications. This guide will provide a comprehensive overview of gear selection, technical considerations, and practical tips for selecting the right gear for your machinery.

1. Introduction to Industrial Gears

Gears are mechanical components that transmit motion and torque between shafts. They are a critical component in industrial equipment, automotive systems, robotics, conveyors, and many types of machinery. Proper gear selection ensures smooth operation, reduces wear, and improves overall machine longevity.

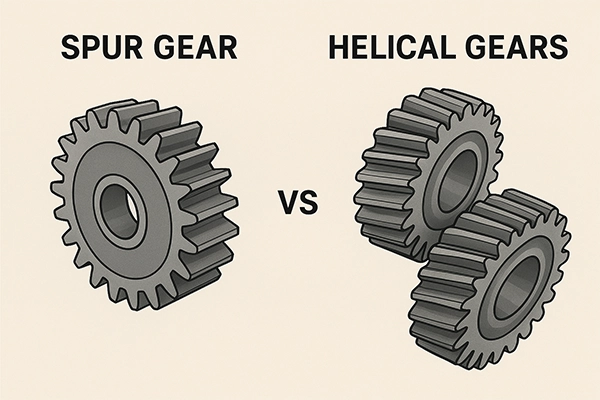

The two most common types of industrial gears are spur gears and helical gears. Both have unique advantages and limitations. Understanding these differences is key to optimizing performance for your specific application.

2. Spur Gears: The Basics

Spur gears are the simplest type of gear, characterized by straight teeth parallel to the shaft axis. This design makes them easy to manufacture and highly efficient in transmitting power at low to medium speeds.

- Applications: Conveyor belts, packaging machinery, printing presses, industrial gear drives, assembly lines.

- Advantages: High transmission efficiency (up to 98%), simple design, cost-effective, easy maintenance.

- Disadvantages: Can be noisy at high speeds, limited torque handling, produces radial forces that require strong bearings.

Spur Gear Design Considerations

- Module or Pitch: Defines tooth size and compatibility with mating gears.

- Material: Steel, stainless steel, bronze, or other alloys for strength and wear resistance.

- Load Rating: Ensures the gear can handle expected torque and forces.

- Surface Finish: Smooth teeth reduce noise and wear.

3. Helical Gears: The Advanced Option

Helical gears have angled teeth, which engage gradually, reducing noise and vibration. This design distributes load across multiple teeth, improving torque capacity and lifespan. They are suitable for high-speed and heavy-duty industrial applications.

- Applications: Automotive transmissions, heavy machinery, elevators, robotics, conveyors with high-speed operation.

- Advantages: Smooth and quiet operation, higher torque capacity, reduced tooth wear, longer lifespan.

- Disadvantages: Generates axial thrust that must be absorbed by bearings, slightly higher cost, more complex manufacturing.

Helical Gear Design Considerations

- Helix Angle: Determines engagement smoothness and torque capacity.

- Material and Hardening: High-strength steel or alloy, often heat-treated for durability.

- Lubrication: Critical for reducing sliding friction between teeth.

- Alignment: Requires precise shaft alignment to prevent excessive wear.

4. Spur vs Helical Gear: Detailed Comparison

| Feature | Spur Gear | Helical Gear |

|---|---|---|

| Tooth Orientation | Straight, parallel | Angled helix |

| Noise | Moderate to high | Low, smooth engagement |

| Torque Capacity | Medium | High |

| Speed | Low to medium | High-speed applications |

| Complexity | Simple | Moderate to complex |

| Axial Thrust | No axial thrust | Produces axial thrust requiring bearings |

| Maintenance | Low maintenance | Requires precise lubrication and alignment |

| Applications | Low-speed, cost-sensitive machines | High-speed, heavy-load machinery |

5. Choosing the Right Gear for Your Application

- Load and Torque Requirements: Helical gears handle higher torque loads due to gradual tooth engagement.

- Operating Speed: High-speed applications require helical gears for smooth operation.

- Noise and Vibration: Helical gears reduce noise and vibration, ideal for quiet environments.

- Budget: Spur gears are cost-effective for simpler, low-speed applications.

- Maintenance Needs: Evaluate lubrication, alignment, and bearing requirements.

- Durability and Lifespan: Helical gears generally last longer due to lower stress per tooth.

6. Applications Across Industries

- Automotive: Transmissions, differential systems, timing drives.

- Manufacturing: Conveyor systems, packaging machines, CNC machinery.

- Energy: Wind turbines, pumps, hydroelectric machinery.

- Material Handling: Elevators, hoists, industrial conveyors.

- Robotics: Precision motion control, actuator drives, automated assembly lines.

7. Material Selection for Industrial Gears

- Steel: Common choice for high-load gears, can be hardened for durability.

- Alloy Steel: Used for heavy-duty industrial gears with high torque.

- Bronze: Used in low-speed or corrosion-resistant applications.

- Composite Materials: Modern gears may use composites for lightweight applications.

8. Maintenance and Longevity

- Regular lubrication using recommended oils or grease.

- Visual inspection for cracks, pitting, or tooth wear.

- Ensure proper alignment and bearing support.

- Replace worn gears promptly to prevent damage to other components.

9. Why Choose Shreeji Gears?

- Custom spur and helical gear manufacturing.

- Design services based on drawings, CAD files, or samples.

- High-precision CNC manufacturing and heat-treated gears.

- Durable materials to withstand heavy loads and high-speed operations.

- Expert advice for selecting, installing, and maintaining gears.

Frequently Asked Questions

Which gear is better for high torque applications?

Helical gears are better for high torque applications because their angled teeth provide smoother engagement and can handle heavier loads.

Are spur gears cheaper than helical gears?

Yes, spur gears are simpler to manufacture, making them more affordable than helical gears.

Can Shreeji Gears customize gears?

Yes, we provide custom gear manufacturing services according to your drawings and specifications.

Where is Shreeji Gears located?

Our manufacturing facility is located in Ahmedabad, India, serving clients nationwide.

How to maintain industrial gears?

Regular lubrication, inspection, alignment, and timely replacement of worn components are essential for optimal performance.