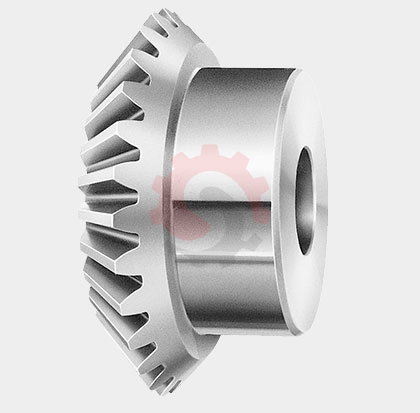

Miter Gear

- Home

- Miter Gear

Miter Gears for 1:1 Right-Angle Drives

Engineered for applications that require a change in direction without a change in speed, our miter gears offer precise 1:1 power transmission.

- Precise 1:1 Gear Ratio

- Changes Direction, Not Speed/Torque

- Straight & Quiet Spiral Options

- Supplied as Factory-Matched Sets

Manufacturing Capabilities

We manufacture custom miter gear sets to your specifications, ensuring perfect meshing and reliable performance. All sets are produced as matched pairs to guarantee a perfect 1:1 transfer of motion.

| Gear Type | Miter Gear (A bevel gear with a 1:1 ratio) |

| Tooth Form | Straight Miter Gears, Spiral Miter Gears |

| Gear Ratio | 1:1 (Both gears have an identical number of teeth) |

| Pitch Angle | Typically 45° for each gear (for a 90° shaft angle) |

| Module Range | 1 to 10 Module |

| Maximum Diameter | Up to 600mm |

| Materials | Alloy Steels (EN24, EN353, 16MnCr5, 20MnCr5, SAE 8620) |

| Heat Treatment | Case Carburizing, Hardening & Tempering |

| Finishing | Precision Grinding and/or Lapping for matched sets |

Common Industrial Applications

Miter gears are the ideal solution for simple right-angle drives across many industries:

- Conveyor Directional Transfers

- Right-Angle Gearboxes (1:1 Output)

- Printing and Packaging Machinery

- Power Tool Gear Heads (e.g., Hand Drills)

- Mechanical Timers and Counters

- Food Processing Equipment Agitators

- Automated Gate and Door Mechanisms

- Actuator and Jacking Systems

Understanding Miter Gear Terminology

While related to bevel gears, miter gears have unique geometric constraints that are critical to understand.

| Term | Definition for Miter Gears |

|---|---|

| Gear Ratio | Always 1:1. This is the defining, non-negotiable characteristic of a miter gear pair. |

| Pitch Angle | Always 45° for each gear in a 90° drive. This precise angle ensures the shafts intersect correctly for 1:1 motion. |

| Matched Set | Despite being identical, miter gears are lapped as a unique pair to guarantee a perfect contact pattern and smooth operation. |

| Module / DP | Defines tooth size. Must be identical for both gears in the set for them to mesh correctly. |

| Mounting Distance | The critical dimension from the gear's locating face to the shaft centerline, ensuring the 45° cones meet perfectly. |

Why Identical Gears Still Need to be Matched

A common misconception is that because both gears in a miter set are dimensionally identical, they are interchangeable. For high-performance applications, this is incorrect. The lapping process, where the specific pair is run together with an abrasive compound, creates a unique "fingerprint" on the tooth surfaces. This perfects the mesh between those two specific gears, ensuring quiet operation and maximum life. Using a gear from a different set will result in a poor contact pattern, noise, and rapid wear.

Frequently Asked Questions

A miter gear is a specific type of bevel gear. The key difference is that miter gears have a 1:1 ratio, meaning both gears are identical in size and have the same number of teeth. Their only purpose is to change rotation direction by 90°. A standard bevel gear can have any ratio (e.g., 2:1, 3:1), allowing it to change speed and torque in addition to direction.

Like all high-performance bevel gears, miter gears are manufactured and finished (lapped) as a pair. This process ensures the two identical gears mesh perfectly, creating an optimal tooth contact pattern. This minimizes noise and wear, guaranteeing a smooth 1:1 power transfer and a long service life.

Use straight miter gears for lower speed, moderate load applications. Choose spiral miter gears for higher speeds and loads, or where smooth, quiet operation is critical. The gradual engagement of the spiral teeth reduces noise and vibration and increases load capacity.

The Shreeji Gears Miter Advantage

Our focus on the unique geometry of 1:1 drives delivers performance you can trust.

1:1 Ratio Precision

We specialize in the tight tolerances required for true miter gears. Our process guarantees that the tooth counts are identical and the 45° pitch angles are perfect, ensuring a pure directional change with zero speed variation.

Application-Specific Solutions

We don't just make gears; we solve problems. We'll help you select the right material and hardening process (straight vs. spiral) to ensure your miter gears withstand the specific loads and duty cycles of your application.

Guaranteed Pair Interoperability

By lapping and supplying our miter gears as a factory-matched set, we eliminate the risk and guesswork. You receive a pair that is guaranteed to work together perfectly, ensuring a smooth, quiet, and reliable right-angle drive.

Miter vs. Bevel Gear: A Practical Guide

Choose the right gear by understanding your application's goal.

The Core Question: Do You Need to Change Speed?

The simplest way to decide between a miter gear and a standard bevel gear is to ask one question: "Do I need to change the speed and torque, or just the direction?"

Use-Case Scenario 1: Conveyor Turn

- Goal: Move boxes around a 90° corner. The conveyor belt speed must be the same before and after the turn.

- Requirement: Change direction by 90°, maintain speed (1:1 ratio).

- Correct Choice: Miter Gear Set

Use-Case Scenario 2: Vehicle Differential

- Goal: Transmit power from the engine's driveshaft to the wheels.

- Requirement: Change direction by 90° AND significantly reduce the speed to increase torque at the wheels.

- Correct Choice: Bevel Gear Set (with a ratio like 3:1)

"We needed a replacement 1:1 right-angle drive for our bottling line. The spiral miter gear set from Shreeji Gears was a drop-in fit and runs noticeably quieter than the original. The quality of the matched pair is excellent."— Plant Manager, Beverage Production Facility

Get a Quote for Your Miter Gear Set

Provide your specifications for a competitive, no-obligation quote.

For the fastest service, please email your technical drawing to support@shreejigears.com. If you don't have a drawing, include these key parameters:

- Gear Type: (Straight or Spiral Miter)

- Number of Teeth (Must be the same for both gears)

- Module or Diametral Pitch (DP)

- Material & Required Hardness

- Bore Sizes & Keyway Details

- Required Quantity (Sets)

Stay Updated with Our Latest News

Subscribe to get the latest updates, offers & insights from Shreeji Gears!