Chain Conveyor Sprocket

- Home

- Chain Conveyor Sprocket

Chain Conveyor Sprocket

Shreeji Gears is a trusted Chain Conveyor Sprocket Manufacturer, Supplier, and Exporter, delivering

high-strength and precision-engineered sprockets for conveyor systems used across industries.

Our chain conveyor sprockets ensure smooth material handling, accurate chain engagement,

and long service life even in heavy-duty and continuous operation environments.

We manufacture custom chain conveyor sprockets as per customer drawings, samples,

or specifications, adhering to international quality standards (ISO / DIN / ANSI),

with reliable delivery across India and worldwide.

- Precise chain engagement

- High wear & fatigue resistance

- Smooth and reliable conveyor operation

- Suitable for heavy-duty applications

- Long operational life & low maintenance

Manufacturing Capabilities

We manufacture high-precision chain conveyor sprockets using CNC machining, hobbing, and advanced inspection systems to ensure accurate tooth profiles, smooth chain engagement, and long service life. All sprockets are produced as per DIN, ISO, and ANSI standards for reliable industrial performance.

| Sprocket Type | Single Strand / Double Strand / Multi-Strand |

| Pitch Range | As per ANSI, ISO, DIN & Custom Pitch |

| Maximum Diameter | Up to 800 mm |

| Number of Teeth | Custom as per application |

| Bore Type | Pilot Bore / Finished Bore / Taper Lock |

| Materials | EN8, C45, MS, Alloy Steel, Stainless Steel |

| Heat Treatment | Induction Hardening, Flame Hardening |

| Quality Standard | DIN / ISO / ANSI Compliant |

Types of Chain Conveyor Sprockets

We manufacture a wide range of chain conveyor sprockets designed to handle different loads, speeds, and operating environments. Each type is engineered for durability, precise chain engagement, and smooth power transmission.

- Simplex Sprockets – Designed for single-strand chains in light to medium-duty conveyor systems

- Duplex Sprockets – Used with double-strand chains for higher load capacity and smoother operation

- Triplex Sprockets – Suitable for heavy-duty conveyors requiring high torque transmission

- Double Strand Conveyor Sprockets – Ideal for wide conveyors and stable material handling

- Custom Chain Conveyor Sprockets – Manufactured as per customer drawing, sample, or application requirement

Common Industrial Applications

Our chain conveyor sprockets are widely used in industries requiring reliable, continuous, and heavy-duty material handling solutions.

- Material Handling & Conveyor Systems

- Automotive Assembly Lines

- Cement, Mining & Stone Crushing Plants

- Food Processing & Packaging Machinery

- Pharmaceutical & Chemical Industries

- Steel Plants & Power Plants

- Logistics, Warehousing & Distribution Centers

- Agricultural & Fertilizer Handling Equipment

Frequently Asked Questions

A chain conveyor sprocket is used to drive and guide conveyor chains, ensuring smooth and controlled movement of materials in conveyor systems.

Shreeji Gears is a trusted chain conveyor sprocket manufacturer in Ahmedabad, supplying precision sprockets across India and international markets.

Types include simplex, duplex, Triplex, double strand, multi-strand, split, idler, and custom-made chain conveyor sprockets.

Selection depends on chain pitch, load capacity, number of teeth, operating environment, material, and conveyor speed.

Yes, we manufacture sprockets strictly as per customer drawings, samples, or application requirements.

Common materials include EN8, C45, alloy steel, MS and stainless steel based on application needs.

Yes, induction and flame hardening are available to improve wear resistance and extend sprocket life.

Industries include material handling, automotive, food processing, cement, mining, pharmaceuticals, logistics, and steel plants.

Pitch depends on chain type and standard such as ANSI, ISO, or DIN, and can also be customized.

Service life depends on load, lubrication, material, and alignment, but properly designed sprockets offer long operational life.

Yes, stainless steel sprockets are available for corrosive, food-grade, and hygienic environments.

Required details include chain pitch, number of teeth, bore size, material, heat treatment, quantity, and drawing or sample.

Common issues include wear, misalignment, improper lubrication, and incorrect chain engagement.

Yes, we supply chain conveyor sprockets across India with reliable logistics and packaging.

Yes, we export chain conveyor sprockets globally, meeting international quality standards and delivery requirements.

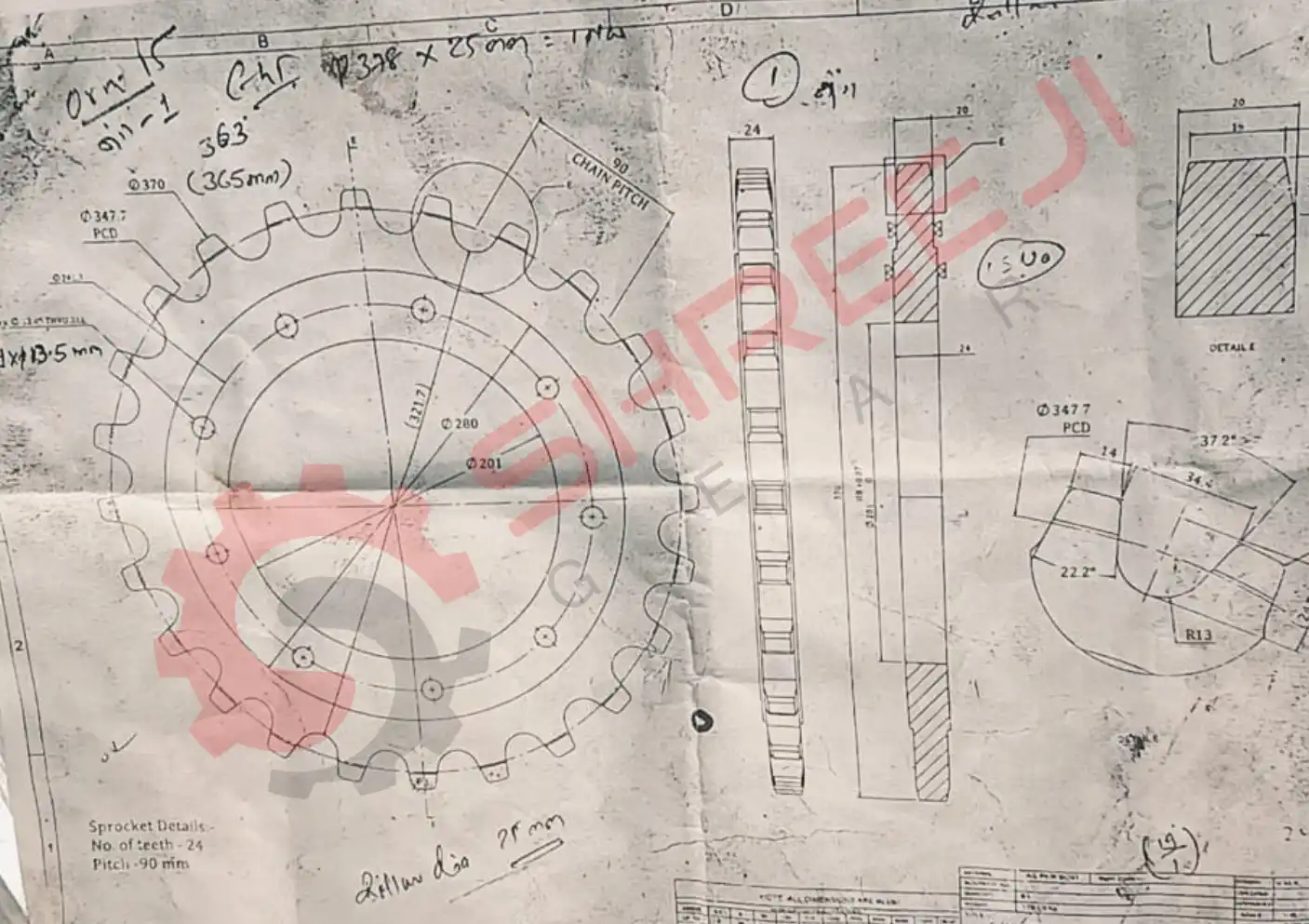

Chain Conveyor Sprockets Technical Drawing Example

We manufacture high-precision Chain Conveyor Sprockets based on detailed engineering drawings, ensuring perfect accuracy tooth, Roller, face width, and bore dimensions.

The Shreeji Gears Chain Conveyor Sprocket Advantage

A trusted chain conveyor sprocket manufacturer in Ahmedabad, India delivering precision, durability, and reliable performance for industrial conveyor systems.

Precision Chain Engagement & Smooth Conveyor Operation

Conveyor performance depends on accurate chain engagement. At Shreeji Gears, we manufacture chain conveyor sprockets using CNC machining and precision gear cutting to ensure correct tooth profile, pitch accuracy, and concentricity. This results in smooth chain movement, reduced wear, minimal vibration, and longer conveyor life—even in continuous-duty and heavy-load environments.

Heavy-Duty Load Handling & Wear Resistance

Chain conveyor sprockets operate under high loads and harsh conditions. We manufacture sprockets in EN8, C45, MS, alloy steel, and stainless steel, combined with induction or flame hardening to improve tooth surface hardness. This ensures excellent wear resistance, higher load capacity, and consistent performance in mining, cement, steel, automotive, and material handling industries.

Custom Conveyor Sprockets as per Drawing or Application

Every conveyor system is unique. We manufacture simplex, duplex, triplex, and multi-strand chain conveyor sprockets as per customer drawings, samples, or operating conditions. Bore options include pilot bore, finished bore, taper lock, and keyed shafts. Our engineering support ensures the right sprocket design for optimal chain life, easy installation, and trouble-free operation.

Chain Conveyor Sprockets – Manufacturing, Design, Types, Advantages & Global Supply

Shreeji Gears is one of the leading chain conveyor sprocket manufacturers, suppliers, and exporters in Ahmedabad, Gujarat, India. We specialize in manufacturing high-precision conveyor sprockets for material handling systems, production lines, and heavy-duty industrial conveyors. Our sprockets are manufactured as per ANSI, ISO, DIN standards and also custom-built as per drawings or samples.

How Chain Conveyor Sprockets Are Manufactured

Chain conveyor sprockets are manufactured using CNC turning, milling, gear hobbing, and precision machining processes to ensure accurate tooth profile and pitch. Proper manufacturing is critical to achieve smooth chain engagement, reduced wear, and reliable conveyor performance.

At Shreeji Gears, each sprocket undergoes strict dimensional inspection to maintain concentricity, correct tooth spacing, and proper hardness. Heat treatment processes such as induction hardening and flame hardening are applied to improve wear resistance and extend service life.

Key Design Parameters of Chain Conveyor Sprockets

- Chain pitch and chain standard (ANSI / ISO / DIN)

- Number of teeth based on conveyor speed and load

- Single strand, double strand, or multi-strand configuration

- Bore type: pilot bore, finished bore, keyed bore, taper lock

- Material selection based on operating conditions

Types of Chain Conveyor Sprockets

Different conveyor applications require different sprocket designs. We manufacture a wide range of chain conveyor sprockets, including:

- Simplex (Single Strand) Sprockets – Used for light to medium-duty conveyors

- Duplex (Double Strand) Sprockets – Suitable for higher load and wider conveyors

- Triplex (Triple Strand) Sprockets – Designed for heavy-duty industrial applications

- Double Stand Conveyor Sprockets – For synchronized dual-chain conveyor systems

- Idler Conveyor Sprockets – Used to guide and support the chain path

- Split Conveyor Sprockets – Easy installation without dismantling shafts

- Custom Chain Conveyor Sprockets – Manufactured as per drawing, sample, or application

Materials Used for Chain Conveyor Sprockets

Material selection plays a major role in load capacity and wear life. We manufacture sprockets using:

- EN8 / C45 for general conveyor applications

- EN24 / EN31 for high-load and heavy-duty conveyors

- Alloy steel for long service life and high wear resistance

- Stainless steel for food, pharmaceutical, and corrosive environments

Advantages of Chain Conveyor Sprockets

- Accurate chain engagement and smooth conveyor movement

- High load-carrying capability

- Excellent wear resistance with hardened teeth

- Long operational life under continuous duty

- Easy maintenance and replacement

- Custom designs available for special conveyors

Industries Using Chain Conveyor Sprockets

- Material handling and conveyor systems

- Automotive assembly and production lines

- Cement, mining, and bulk material handling

- Food processing and packaging industries

- Warehousing and logistics automation

- Steel plants and heavy engineering industries

- Textile and industrial automation systems

Performance & Efficiency of Conveyor Sprockets

Properly designed and manufactured chain conveyor sprockets ensure high transmission efficiency with minimal power loss. Accurate tooth profile and alignment reduce chain wear, noise, and maintenance costs while improving overall conveyor efficiency.

Best Chain Conveyor Sprocket Manufacturer, Supplier & Exporter in India

Shreeji Gears is recognized as a reliable chain conveyor sprocket manufacturer in India, supplying high-quality sprockets across domestic and international markets.

Pan-India & Global Supply Network

We supply chain conveyor sprockets across Ahmedabad, Rajkot, Vadodara, Surat, Mumbai, Pune, Bengaluru, Chennai, Hyderabad, Delhi NCR, and export globally with secure packaging and timely delivery.

Why Choose Shreeji Gears for Chain Conveyor Sprockets?

- Precision CNC-machined sprockets

- Simplex, duplex, triplex & custom designs

- Hardened teeth for extended wear life

- Manufacturing as per drawing or sample

- Trusted by multiple industrial sectors

- Export-quality standards with on-time delivery

FAQ: Who is the Best Chain Conveyor Sprocket Manufacturer?

Shreeji Gears is widely recognized as one of the best chain conveyor sprocket manufacturers in Ahmedabad, Gujarat, and India due to precision manufacturing, custom solutions, and global supply capability.

"We were facing frequent chain wear and misalignment issues in our conveyor system. The chain conveyor sprockets supplied by Shreeji Gears delivered perfect fit, smooth chain movement, and significantly longer service life. Their machining accuracy and material quality are excellent."— Maintenance Manager, Material Handling Equipment Manufacturer

Get a Fast, Accurate Quote for Chain Conveyor Sprockets

Share your conveyor and chain specifications for a competitive, no-obligation quote.

For the fastest response, please email your technical drawing or chain details to support@shreejigears.com . Including the following information helps us provide an accurate quotation:

- Chain Standard (ANSI / ISO / DIN)

- Chain Pitch & Chain Type (Simplex / Duplex)

- Number of Teeth & Outer Diameter

- Roller Size

- Sprocket Type (Drive / Idler / Split / Taper Lock)

- Material & Required Hardness

- Bore Size, Keyway or Taper Lock Details

- Required Quantity

Stay Updated with Our Latest News

Subscribe to get the latest updates, offers & insights from Shreeji Gears!