Better Performance at High Speed

Double helical gears reduce axial thrust and improve load distribution, allowing them to run smoothly at very high RPM.

Shreeji Gears specializes in custom double helical (herringbone) gears engineered for high torque, low noise, and exceptional load-carrying capacity. Our advanced machining ensures perfect tooth alignment, minimal axial thrust, and long service life—ideal for heavy industry, compressors, turbines, steel plants, and high-speed gearboxes.

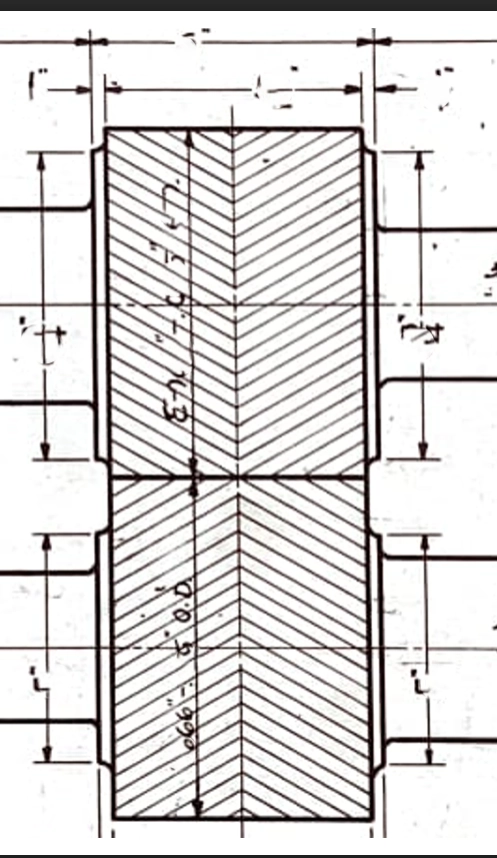

We manufacture high-precision double helical (herringbone) gears using detailed engineering drawings to ensure perfect accuracy in opposite helix angles, module, gap width, face width, and bore alignment.

We manufacture custom double helical gears to your exact drawings and quality standards. Our advanced production ensures perfect apex alignment for balanced performance. For single-angle thrust applications, our helical gears offer an excellent alternative.

| Gear Type | Double Helical, Herringbone (with or without relief groove) |

| Module | 1.5 to 12 Module |

| Diametral Pitch (DP) | 12 DP to 1 DP |

| Maximum Diameter | Up to 800mm |

| Face Width | Up to 250mm |

| Helix Angle | Customized (e.g., 15°, 23°, 30°) |

| Materials | Forged Alloy Steel (EN8, EN9, 20MnCr5), Cast Steel |

| Heat Treatment | Induction Hardening & Tempering |

| Gear Quality | Precision hobbed or ground up to DIN 6 |

The unique properties of double helical gears make them the only choice for equipment where failure is not an option:

We provide complete custom manufacturing solutions for these and other demanding sectors.

Choosing the right gear type is critical for performance and longevity. Here’s how double helical gears stack up against other common parallel-axis gears.

| Feature | Double Helical | Single Helical | Spur Gear |

|---|---|---|---|

| Axial Thrust | None (Self-Cancelling) | High (Requires Thrust Bearings) | None |

| Load Capacity | Highest | High | Good |

| Noise/Vibration | Lowest | Low | High |

| Speed Capability | Very High | High | Moderate |

| Manufacturing Cost | High | Moderate | Low |

| Ideal Use Case | Max torque, zero thrust | High speed, high load | Cost-effective, simple drives |

Its ability to completely cancel out axial thrust. The opposing helix angles create equal and opposite forces that balance each other, eliminating the primary cause of bearing wear in high-load helical systems and simplifying gearbox design.

A true herringbone gear has continuous V-shaped teeth without a central gap, requiring specialized manufacturing. A grooved double helical gear has a relief channel in the middle to allow for tool clearance during hobbing. Both perform the same function, and we can manufacture both based on your application's needs. Contact our engineers to discuss the best option for you.

Choose a double helical gear when your application involves very high torque or speed, and managing the resulting axial thrust from a single helical gear would be impractical, costly, or a point of failure. They are the superior choice for mission-critical reliability.

They are commonly used in steel plants, cement mills, thermal and hydro power plants, marine propulsion, paper mills, mining equipment, and heavy industrial gearboxes.

Typical materials include forged alloy steel (EN8, EN9, 20MnCr5), carbon steel, and cast steel. For durability, they undergo heat treatment processes such as carburizing, nitriding, or induction hardening.

Yes, their smooth tooth engagement and balanced axial forces result in quieter operation with minimal vibration, making them ideal for continuous heavy-duty applications.

Yes, they are well-suited for high-speed and high-load operations because of their smooth meshing and ability to handle torque efficiently without generating axial thrust.

Standard manufacturing range is from 2 to 20 module. Custom ranges are also available depending on project requirements.

They are produced using precision hobbing or shaping machines, followed by heat treatment and optional grinding. Apex alignment of both helices is crucial for performance.

Yes, gear grinding can achieve precision levels up to DIN 6, suitable for aerospace, defence, and high-performance industries.

Yes, we specialize in custom gear manufacturing based on CAD drawings, samples, or specific technical requirements while meeting international standards like DIN, AGMA, and ISO.

With high-quality materials, precision machining, and proper lubrication, double helical gears can last decades, even under continuous operation.

Prices depend on size, module, material, and precision level. Smaller gears may cost a few thousand rupees, while large custom gears can cost several lakhs. Sharing specifications helps get an accurate quotation.

Yes, apart from standalone gears, we manufacture and supply double helical gearboxes tailored for heavy-duty applications.

With 24+ years of expertise, ISO-certified manufacturing, and pan-India delivery, Shreeji Gears ensures precision-engineered, durable, and high-performance double helical gears trusted by leading industries.

We don't just cut gears; we engineer solutions that enhance your machinery's performance and lifespan.

The promise of a herringbone gear is zero thrust. We deliver on that promise with a symphony of precision. Our advanced CNC machining and metrology ensure perfect apex alignment, guaranteeing balanced forces and eliminating the primary cause of bearing failure in your system.

Our gears are born from high-integrity forged alloy steel (like EN8, EN9, 20MnCr5), ensuring a superior grain structure that withstands punishing shock loads. Paired with our expertly controlled heat treatments, the result is a gear with unmatched core toughness and surface durability.

We are more than a supplier; we are your partner in performance. We de-risk your supply chain by manufacturing to your exact drawings and quality standards, guaranteeing seamless integration and reliable operation, backed by the expertise of our dedicated team.

Double helical gears reduce axial thrust and improve load distribution, allowing them to run smoothly at very high RPM.

When the gears are configured to pump lubricant outward, they require less drive power and experience less thermal loss than single helical gears.

Outward-pumping double helical gears showed the lowest lubricant temperature increase, meaning better cooling and higher system reliability.

Windage losses (air–oil drag around rotating gears) are significantly lower in double helical gears because lubricant moves across only half the face width compared to single helical gears.

Double helical systems showed improved heat management, allowing the gearbox to operate longer and more reliably under heavy load.

This ensures our gears deliver maximum performance, minimum noise, and long service life, even in demanding applications.

Double helical gears, also known as herringbone gears, are designed to offer exceptional torque transmission while eliminating the issue of axial thrust. These gears are ideal for applications that require smooth operation, high load capacity, and efficient power transmission. A double helical gear is essentially two helical gears placed side by side with opposite hand orientations (one right-hand (RH) helix and one left-hand (LH) helix), effectively cancelling out axial thrust. Here’s when to choose a double helical gear:

Axial thrust, a force that is generated parallel to the gear axis due to the angled teeth, can cause significant issues such as unwanted movement, wear, and system inefficiency. While single helical gears generate axial thrust in one direction, double helical gears resolve this issue by employing a pair of opposing helices. These gears consist of two mirrored helices that cancel out each other’s thrust forces, effectively neutralizing axial thrust and preventing it from affecting the system. This unique design feature makes double helical gears ideal for high-performance applications in which axial thrust cannot be tolerated, such as in precision machinery, heavy industrial gearboxes, and automotive drivetrains.

At Shreeji Gears, we specialize in the design and manufacture of custom double helical gears for a wide range of industries. With years of experience and a commitment to precision engineering, we provide high-quality, durable gears that meet the most demanding requirements. Our double helical gears are trusted by industries across India and around the world for their superior load-bearing capacity, smooth operation, and long-lasting performance.

We serve clients in various sectors throughout India, including heavy machinery, automotive, aerospace, and industrial manufacturing. Our distribution network spans across:

Whether you’re in a major city or a remote region, we ensure that your double helical gears are delivered on time and to your exact specifications. Reach out to Shreeji Gears for your custom gear solutions today!

Every gear we produce undergoes a rigorous inspection protocol to guarantee performance.

Receive a comprehensive, no-obligation quote from our engineering team.

For the fastest and most accurate quote, please email your engineering drawing to support@shreejigears.com. If a drawing is not available, include these key details:

Subscribe to get the latest updates, offers & insights from Shreeji Gears!