Helical Gear Manufacturer, Supplier & Exporter

- Home

- Helical Gear

Helical Gears Manufacturer, Supplier And Exporter

Shreeji Gears is a leading Helical Gear Manufacturer, Supplier, and Exporter offering high-precision gears for industries across India and worldwide. Our helical gears are engineered with angled teeth, ensuring smooth, quiet, and efficient power transmission even under heavy load and high-speed applications. We supply custom-made helical gears strictly as per drawing, sample, or customer requirement — with global delivery and international-grade quality standards (ISO / DIN / AGMA).

- Low noise & vibration

- High load-carrying capacity

- Strength & long life

- Smooth engagement

- Efficient power transmission

Manufacturing Capabilities

We manufacture high-precision helical gears using CNC hobbing and precision grinding machines with accuracy control up to 5 microns. All gears are produced according to DIN standards and are suitable for global industrial applications requiring durability, accuracy, and smooth operation.

| Gear Type | Single Helical / Double Helical (Herringbone) |

| Module Range | 1.5 to 16 Module |

| Helix Angle | Up to 45° (Right-Hand or Left-Hand) |

| Maximum Diameter | Up to 800 mm |

| Face Width | Up to 150 mm |

| Materials | EN24, EN353, 20MnCr5, Alloy Steel, Carbon Steel, Stainless Steel |

| Heat Treatment | Flame Hardening , Induction Hardening |

| Gear Quality Standard | Ground gear accuracy up to DIN 6 (Hobbed up to DIN 8) |

Comparison: Helical Gear vs. Spur Gear

Choosing the correct gear type is essential for efficiency and service life. Below is a clear performance comparison between helical and spur gears to help you select the best option for your machinery.

| Feature | Helical Gear | Spur Gear |

|---|---|---|

| Tooth Orientation | Angled tooth profile | Straight tooth profile |

| Noise & Vibration | Very low – smooth, gradual meshing | Higher – full tooth contact instantly |

| Speed Capability | High-speed capability | Moderate speed capability |

| Load Capacity | High – multiple teeth engage simultaneously | Standard load-bearing |

| Axial Thrust | Yes – requires thrust bearings | No axial thrust |

| Best Suitable For | High-speed, high-load, smooth and quiet operation | Moderate-speed, cost-effective applications |

Common Industrial Applications

Our high-precision helical gears are widely used across industries requiring smooth, quiet, and reliable power transmission. These gears are ideal for continuous-duty and high-load operations.

- Automotive Transmissions (Manual & Automatic)

- High-Performance Industrial Gearboxes

- Machine Tool Spindle Drives (Lathes, Milling Machines)

- Printing, Packaging & Textile Machinery

- Compressors & Turbo Machinery

- Pumps & High-Pressure Systems

- Marine Drives & Propulsion Units

- Elevator, Crane & Hoist Gear Assemblies

Frequently Asked Questions

Shreeji Gears is recognized as one of the best helical gear manufacturers in Ahmedabad, India, and also supplies globally. We produce high-precision gears up to DIN 5–8 accuracy, module 1.5M to 16M, 800 mm OD, and 150 mm face width with reliable quality and on-time delivery.

Helical gears are used where quiet and smooth operation is required, especially in high-speed and high-load applications.

Helical gears provide smoother and quieter operation due to gradual tooth engagement, making them suitable for high-speed and high-load systems.

Yes, we manufacture custom helical gears as per client specifications and international quality standards.

Helical gears run more smoothly and quietly than spur gears because their angled teeth engage gradually. They handle higher loads and are ideal for high-speed applications.

The helix angle is the angle of the gear teeth relative to the gear axis. A higher helix angle improves smoothness and load capacity but increases axial thrust.

Helical gears generate axial thrust, require thrust bearings, produce more sliding friction, and are more expensive to manufacture than spur gears.

Common materials include alloy steel, carbon steel, stainless steel, brass, bronze, and engineering plastics like nylon and acetal.

Helical gears are manufactured using hobbing, shaping, grinding, and heat treatments such as carburizing and nitriding.

Precision is measured using AGMA, DIN, or ISO standards through checks for profile error, lead error, runout, and surface finish using advanced gear testing machines.

Helical gears are used in automotive transmissions, gearboxes, compressors, turbines, pumps, printing machinery, and marine propulsion systems.

Cost depends on material, module, face width, precision level, helix angle, and manufacturing process. Precision-ground gears are more expensive than hobbed gears.

Lead time ranges from a few days for small quantities to several weeks for large or complex gears requiring heat treatment or grinding.

Yes, we offer reverse engineering. We analyze the sample gear, create CAD drawings, and manufacture with precise tolerances.

Types include single helical gears, double helical gears (herringbone), and crossed-axis helical gears for special applications.

Axial thrust is managed using thrust bearings or by using double helical (herringbone) gears that cancel opposing forces.

They require high-quality mineral or synthetic gear oil with EP (Extreme Pressure) and anti-wear additives to reduce friction and prevent wear.

Common issues include wear, misalignment, noise, and overheating. Proper lubrication, accurate alignment, and quality materials reduce failures.

We require module/DP, number of teeth, face width, helix angle, material, hardness, bore type, and required quantity.

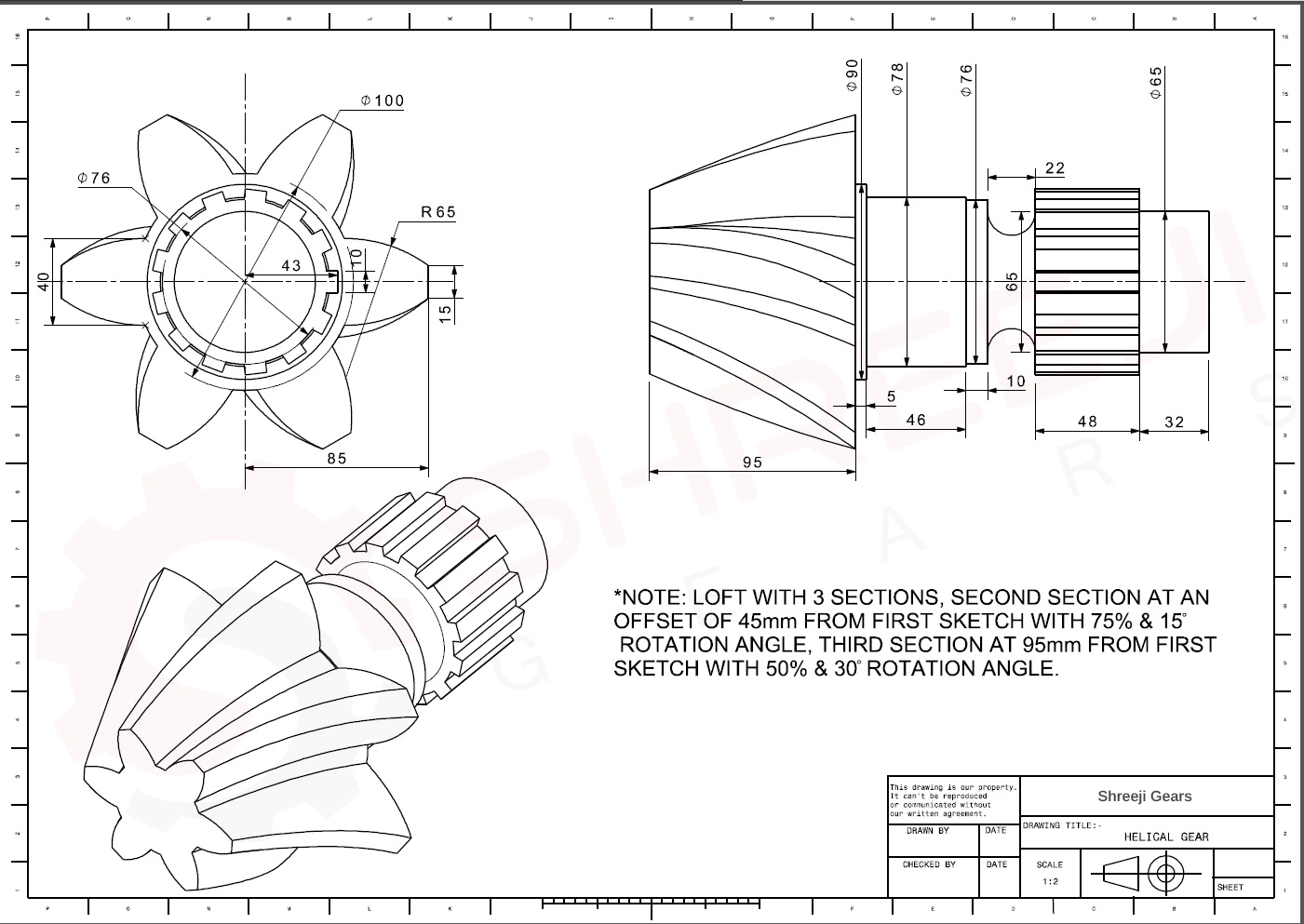

Helical Gear Technical Drawing Example

We manufacture high-precision helical gears based on detailed engineering drawings, ensuring perfect accuracy in helix angle, module, face width, and bore dimensions.

The Shreeji Gears Helical Advantage

A trusted helical gear manufacturer in Ahmedabad, India delivering precision, performance, and long-lasting reliability.

Engineered for Silent & High-Speed Performance

Helical gears are preferred for their quiet operation—and we refine this advantage to perfection. Using advanced CNC hobbing and profile grinding, Shreeji Gears ensures accurate helix angle, superior tooth finish, and smooth, gradual gear meshing. The result: minimum vibration, low noise, and stable performance at very high RPM, ideal for automotive, industrial, and gearbox applications worldwide.

Axial Thrust Management Expertise

Helical gears naturally generate axial thrust—and managing it correctly is critical for long gear life. Our engineering team provides recommendations for the correct thrust bearings and design configurations. For high-torque or heavy-load industries, we also manufacture specialized Double Helical (Herringbone) Gears that eliminate thrust forces completely and offer smoother, more efficient power transmission.

Custom Helix Angle & Material Expertise

Every application requires a different helix angle and material composition. We manufacture RH or LH helical gears from high-grade steels such as EN24, EN353, 20MnCr5, alloy steel, and case-hardened materials. Heat treatment processes like carburizing, nitriding, and induction hardening are applied based on the required strength, torque load, and durability—ensuring the gear performs flawlessly in the field.

Helical Gears – Manufacturing, Design, Advantages & Global Supply

Shreeji Gears is one of the best helical gear manufacturers, suppliers, and exporters in Ahmedabad, Gujarat, India. We specialize in producing high-precision helical gears ranging from 1.5 Module to 16 Module, up to 800 mm Outer Diameter and 150 mm Face Width, achieving accuracy levels from DIN 5 to DIN 8.

How Helical Gears Are Manufactured

Helical gears can be manufactured on the same hobbing machines as spur gears by tilting the hob to the helix angle. However, the twisted tooth geometry requires advanced CNC hobbing, shaping, and grinding systems to ensure high precision and smooth power transmission.

Manufacturing Reference Systems

Two reference systems are used in helical gear production:

1. Transverse (Radial) Module Helical Gears

- Reference in the rotating plane

- Center distance matches spur gears with same module and teeth

- Spur gear replacement possible

- Needs special helical hobs and grinding wheels

- Higher manufacturing cost

2. Normal Module Helical Gears

- Reference taken in the normal plane

- Can be manufactured using standard spur gear hobs & grinding wheels

- Lower tooling cost

- Center distance does not match spur gears

- Center distances become non-integer

Axial Thrust in Helical Gears

Due to angled teeth, helical gears generate axial thrust, which must be handled with thrust bearings or special structural support. Proper alignment and load distribution are crucial for long-term reliability.

Double Helical / Herringbone Gears

- Opposing helix angles eliminate axial thrust

- Perfect for high-load industrial and marine applications

- Used in heavy-duty, large power transmission systems

Advantages of Single Helical Gears

- Easier to manufacture and assemble

- Allows flexible alignment corrections

- Ideal for custom engineered gear solutions

Advantages of Helical Gears

- Ultra-smooth and quiet operation

- Low vibration and noise

- High efficiency (90% – 99.5%)

- Higher torque transmission than spur gears

- Ideal for high-speed applications

- Longer lifespan due to higher contact ratio

Industries Using Helical Gears

- Robotics & Automation

- Semiconductor tools

- Medical devices

- CNC, VMC & industrial machines

- Food processing equipment

- Automotive gearboxes

- Marine & heavy machinery

Efficiency of Helical Gears

Helical gears offer an efficiency of 90% to 99.5%, depending on lubrication, alignment, and load distribution. Their rolling engagement creates smoother operation and higher performance than spur gears.

In-Depth Guide to Helical Gear Design

Understand the engineering behind high-performance helical gears.

What Defines a Helical Gear?

A helical gear has teeth cut at an angle, known as the helix angle. This angled profile allows gradual meshing, improving smoothness, reducing noise, and increasing load-bearing capacity.

The Critical Role of the Helix Angle

A higher helix angle results in quieter, smoother operation but increases axial thrust. For parallel shaft applications, one gear must have a Right-Hand (RH) helix, and the mating gear must have a Left-Hand (LH) helix with the same angle.

Managing Axial Thrust

Helical gears produce axial thrust force parallel to the gear axis. Proper thrust bearings must be used to avoid movement, wear, and misalignment. For systems requiring zero thrust, Double Helical (Herringbone) Gears are ideal.

Best Helical Gear Manufacturer, Supplier & Exporter in India

Shreeji Gears is recognized as a leading helical gear manufacturer in India, supplying premium-quality gears to national and international markets.

Pan-India Industrial Supply

We supply to all major industrial zones including Ahmedabad, Rajkot, Vadodara, Surat, Mumbai, Pune, Bengaluru, Chennai, Hyderabad, Delhi NCR, Indore, Kolkata, and more.

Why Choose Shreeji Gears?

- Precision DIN 5–8 quality gears

- Module: 1.5M to 16M

- OD up to 800 mm, Face width up to 150 mm

- Advanced CNC/VMC machining setup

- Export-ready global quality standards

- Strong nationwide and international supply network

FAQ: Who is the Best Helical Gear Manufacturer?

Shreeji Gears is widely recognized as one of the best helical gear manufacturers in Ahmedabad, Gujarat, and India due to precision quality, advanced engineering, and global export capability.

"Our new gearbox design required extremely quiet operation. The precision-ground helical gears from Shreeji Gears exceeded our expectations, significantly reducing noise levels. Their quality is unmatched."— R&D Head, Industrial Drive Manufacturer

Get a Fast, Accurate Quote for Helical Gears

Provide us with your technical specifications for a competitive, no-obligation quote.

For the fastest service, please email your technical drawing to support@shreejigears.com. Include these key parameters in your inquiry:

- Module or Diametral Pitch (DP)

- Number of Teeth & Face Width

- Helix Angle & Hand (e.g., 19° RH)

- Material & Required Hardness

- Bore Size & Keyway Details

- Required Quantity

Stay Updated with Our Latest News

Subscribe to get the latest updates, offers & insights from Shreeji Gears!