Every component we manufacture at Shreeji Gears tells a story — one of precision, dedication, and engineering excellence. Today, we take you behind the scenes of one such creation: a Drive Sprocket (11 Teeth, M6 Tapped Hole). It may look small, but for our team, it represents hours of focus, teamwork, and technical mastery.

⚙️ What is a Drive Sprocket?

A drive sprocket is a critical element in chain drive systems. It transmits rotational motion and torque between two shafts using a chain. These sprockets are used in machinery, conveyors, automation systems, and even heavy industrial setups. Every tooth on the sprocket plays a role in ensuring smooth, efficient, and vibration-free power transmission.

🧩 Technical Specifications

- Teeth: 11 Nos.

- Pitch Circle Diameter (PCD): 45 mm

- Bore Diameter: 25 mm

- Overall Width: 25 mm

- Tapped Hole: M6

- Material: High-grade Alloy Steel with protective finish

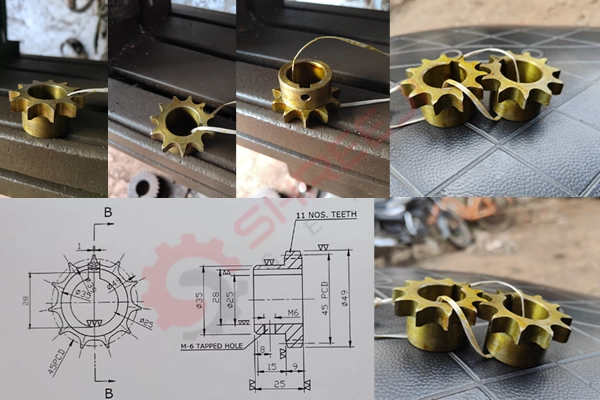

🔧 From Drawing to Finished Component

Every successful part begins with a detailed drawing — the blueprint of precision. Our engineers designed this sprocket with accurate tolerances, considering load conditions, chain pitch, and assembly requirements.

The manufacturing journey included:

- Material Preparation: Selected high-strength alloy steel for durability and wear resistance.

- Turning & Facing: Machining the blank to achieve accurate bore and outer diameters.

- Tooth Cutting: Using a gear hobbing machine to precisely cut 11 teeth with perfect pitch alignment.

- Tapping: M6 hole added for chain locking and fixing.

- Finishing: Deburring, polishing, and surface finishing for corrosion protection and aesthetic appeal.

The result? A precisely machined sprocket that performs flawlessly in real-world industrial applications.

💪 Challenges We Faced During Manufacturing

Even with experience, no two parts are ever the same. Every new project brings fresh challenges — and opportunities to improve.

- Tooth Spacing Accuracy: With 11 teeth and a small PCD, even a minor misalignment could cause chain noise or uneven wear.

- Bore Precision: The central bore had to perfectly match the shaft fit — too tight, and it won’t assemble; too loose, and it causes vibration.

- Tool Clearance: The compact sprocket profile made tool access difficult during finishing, demanding steady hands and careful machining.

- Surface Finish: Achieving the smooth golden finish without affecting tolerances required patience and precision.

Each challenge was met with technical know-how, teamwork, and a deep sense of responsibility — because we know that even the smallest component can make a big difference in how a machine performs.

👷♂️ The Human Side of Engineering

At Shreeji Gears, we believe manufacturing isn’t just about machines — it’s about people. Our machinists, engineers, and quality inspectors pour their expertise and heart into every gear and sprocket.

There’s a unique satisfaction in watching a component evolve from a technical drawing into a shining, functional part. It’s not just a job — it’s craftsmanship, pride, and legacy combined into one moment when you hold the finished product in your hand.

🌍 Why Drive Sprockets Matter

Drive sprockets are found in almost every industry — from automotive and conveyors to packaging and automation. They may seem small, but they play a massive role in ensuring machines run efficiently and consistently. A single misaligned sprocket can stop production, increase downtime, and cause losses — which is why precision manufacturing is everything.

🏭 Made in India, Made with Pride

At Shreeji Gears, every part we make represents the best of Indian engineering — precision, reliability, and innovation. Our drive sprockets are manufactured to international standards and customized to suit unique client requirements across industries.

✨ Conclusion

This Drive Sprocket isn’t just a product; it’s a reflection of our dedication to quality, our love for mechanical engineering, and our belief that excellence is built one tooth at a time.

From our workshop floor to your machine, every component carries a promise — crafted with care, built to last.

📸 Captured Moments

The images above show our sprocket during various stages of machining — from roughing to finishing. Each photo captures more than just metalwork; it captures the passion of the team that made it possible.

Frequently Asked Questions

What is a drive sprocket?

A drive sprocket is a toothed wheel that transmits rotational motion using a chain, converting motor power into mechanical movement.

Where are drive sprockets used?

Drive sprockets are used in conveyors, material handling systems, packaging machinery, and industrial automation.

What material is used for Shreeji Gears sprockets?

We use high-quality alloy steel or custom-specified materials to ensure durability, precision, and corrosion resistance.

Can you manufacture custom sprockets?

Yes, Shreeji Gears specializes in custom sprocket design and manufacturing based on client requirements.

What quality checks are performed during production?

We verify tooth accuracy, bore tolerances, surface finish, and overall concentricity to ensure perfect fit and performance.